5 Reasons Why the Cnc Horizontal Machining Center is the Best Investment for Your Business

In the rapidly evolving landscape of modern manufacturing, the investment in cutting-edge technology is not just advantageous; it’s essential for sustained competitiveness. One such transformative technology is the CNC Horizontal Machining Center, which has been gaining traction among manufacturers seeking precision, efficiency, and versatility. According to a report by MarketsandMarkets, the global CNC machine market is projected to grow from USD 63 billion in 2020 to USD 85 billion by 2025, underscoring the increasing reliance on advanced machining solutions.

The CNC Horizontal Machining Center stands out in this growth, offering superior rigidity and greater thermal stability compared to vertical counterparts, leading to enhanced machining accuracy and reduced cycle times. By investing in a CNC Horizontal Machining Center, businesses can leverage these advantages to optimize production workflows and ensure higher quality outputs, ultimately driving profitability and growth in a competitive arena.

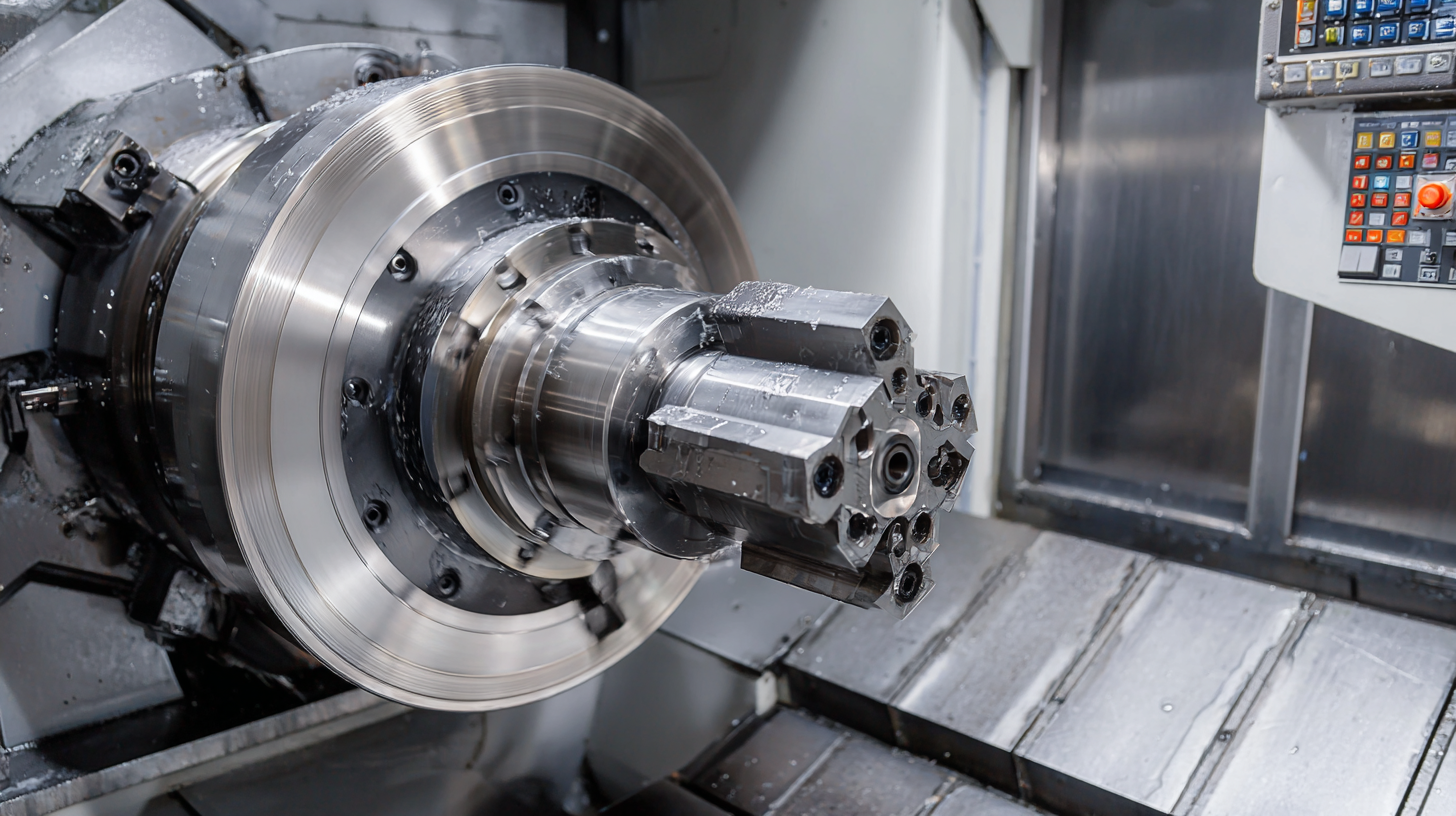

The Efficiency Upgrade: Enhancing Production Speed with CNC Horizontal Machining Centers

Investing in a CNC horizontal machining center can significantly enhance your production speed, giving your business a competitive edge. These machines allow for efficient operation by minimizing setup times and reducing cycle times. The horizontal design offers better gravity-assisted chip removal, leading to quicker processing on complex parts. As a result, businesses can produce higher volumes with improved precision, ensuring that they meet customer demands swiftly and effectively.

To leverage the full potential of CNC horizontal machining centers, consider implementing automation features such as pallet changers. This can streamline workflow by reducing idle time between operations. Additionally, regular maintenance and scheduling machine downtime for inspections can prevent unexpected breakdowns and ensure consistent performance.

Furthermore, investing in skilled operators who are trained to utilize these machines can lead to optimal production outcomes. Encourage ongoing training and development to keep your team updated on the latest techniques and technologies in CNC machining. Building a culture of continuous improvement not only enhances productivity but also fosters innovation within your manufacturing processes.

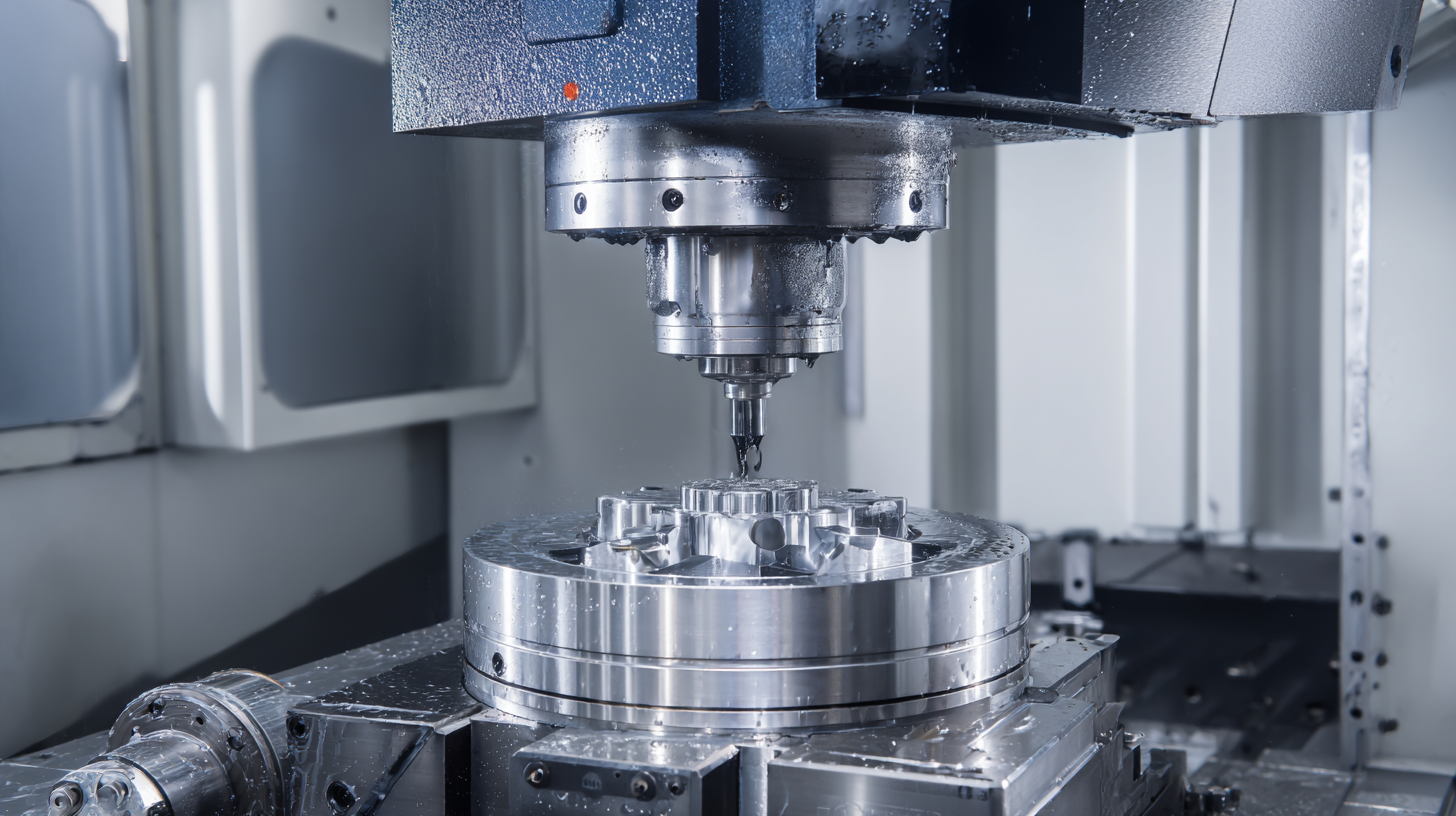

Precision Redefined: Achieving Superior Accuracy in Complex Parts Manufacturing

The CNC horizontal machining center has become an essential asset for businesses aiming to elevate their manufacturing capabilities. One of the standout features of this technology is its ability to achieve superior accuracy in complex parts manufacturing. Unlike traditional machining methods, CNC horizontal centers utilize advanced computer-aided design and programming, enabling them to execute precise cuts and intricate geometries with unparalleled consistency. This level of precision is crucial for industries where small tolerances can mean the difference between a product’s success or failure.

Furthermore, the design of horizontal machining centers allows for improved chip removal and better coolant flow, which not only enhances the machining process but also contributes to the longevity of the tools being used. This streamlined efficiency not only reduces downtime but also ensures that the end products maintain their dimensional integrity. Companies that invest in CNC horizontal machining technology find themselves at a competitive advantage, as they can produce high-quality parts more rapidly, meeting the increasingly stringent demands of their customers while optimizing their operational workflows.

Cost-Effectiveness: Long-Term Savings with CNC Horizontal Machining Investments

Investing in CNC horizontal machining centers offers substantial long-term savings for businesses, particularly in the manufacturing sector. The transition from vertical to horizontal machining may initially seem daunting and costly; however, shops that have made this shift often find it significantly more valuable over time. The enhanced productivity derived from the increased efficiency of horizontal machining translates directly into reduced operational costs and higher output. This efficiency allows businesses to fulfill larger orders swiftly, ultimately improving profit margins.

Additionally, the cost-effectiveness of CNC technology often parallels that of robotics in manufacturing. Just as robots can lead to labor cost reductions and amplified production capacity, CNC horizontal machining centers streamline processes and minimize waste. The precision and versatility of these machines enable manufacturers to tackle complex tasks without the need for extensive manual intervention. Adopting CNC horizontal machining not only boosts output but also fosters innovation, allowing businesses to remain competitive in an evolving market.

Versatility in Manufacturing: Adaptability to Various Industries and Applications

The CNC horizontal machining center (HMC) is revolutionizing the manufacturing landscape, thanks to its remarkable versatility. One of the standout features of the HMC is its ability to adapt to a wide range of industries and applications.

Whether it’s aerospace, automotive, or medical device manufacturing, the horizontal machining center can accommodate diverse materials and complex geometries, making it an invaluable asset for businesses looking to enhance their production capabilities.

Another significant advantage of the HMC is its efficiency in multi-tasking operations. With the capability to perform milling, drilling, and tapping all in one setup, manufacturers can reduce the lead time and improve productivity.

This adaptability not only streamlines workflows but also minimizes the need for multiple machines, allowing businesses to optimize their floor space and reduce operational costs. By investing in a CNC horizontal machining center, companies position themselves to meet the evolving demands of various sectors while maintaining a competitive edge in a fast-paced market.

User-Friendly Technology: Simplifying Operations with Advanced CNC Features

In today’s fast-paced manufacturing environment, operational efficiency is paramount. The CNC horizontal machining center stands out as an invaluable asset, primarily due to its user-friendly technology that simplifies complex operations. With advanced CNC features, operators can easily program and adjust settings, significantly reducing the learning curve for new users. This accessibility enables businesses to make the most of their machinery without the need for extensive training, translating into faster production times and reduced labor costs.

Moreover, the intuitive interface of modern CNC controls allows for real-time monitoring and quick adjustments. This capability not only enhances productivity but also minimizes the chances of error in the machining process. Operators can easily switch between different projects with minimal downtime, ensuring that production schedules are met efficiently. The fusion of advanced technology and user-centric design in CNC horizontal machining centers empowers businesses to optimize their workflows and maintain a competitive edge in the industry.