Exploring Industry Trends at 2025 Canton Fair with 4 Axis CNC Machining Center Innovations

As the 138th Canton Fair approaches in 2025, it promises to showcase significant advancements in various industries, notably in the realm of manufacturing technology. Among the innovations highlighted will be the 4 Axis CNC Machining Center, a revolutionary tool that is reshaping production processes and enhancing precision in machining. This technology allows for complex geometries and improved efficiency, making it an essential asset for manufacturers aiming to stay competitive in the global market.

Attendees will have the opportunity to explore the latest features and capabilities of 4 Axis CNC Machining Centers, as well as how they can be integrated into existing workflows to boost productivity. The fair serves as a pivotal platform for industry professionals to connect, share insights, and discover groundbreaking solutions that will define the future of manufacturing.

Emerging Trends in CNC Machining at the 2025 Canton Fair

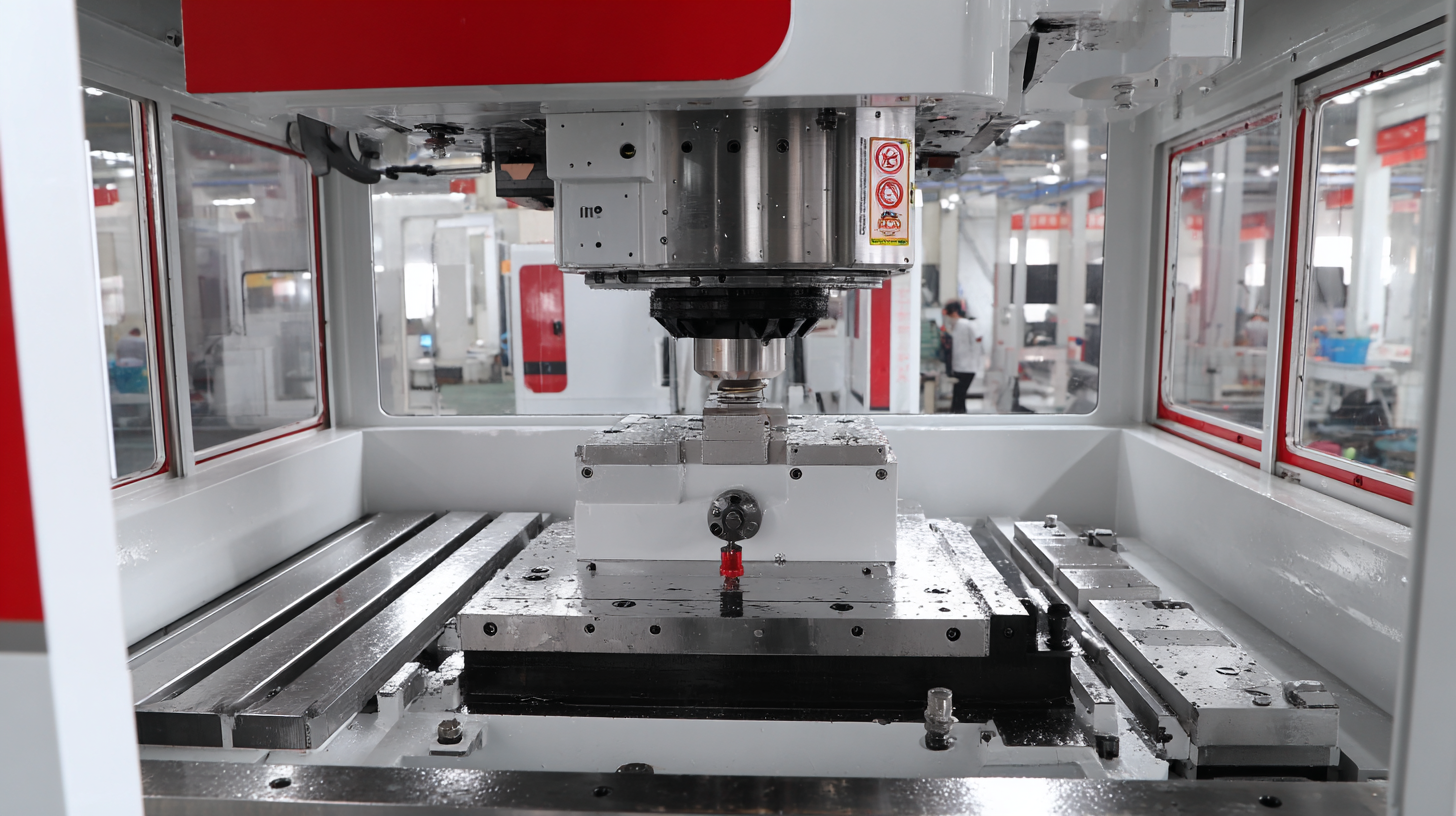

At the 2025 Canton Fair, the spotlight on CNC machining is unmistakable, showcasing a surge of innovations that are set to redefine the industry. The emergence of 4-axis CNC machining centers demonstrates a pivotal shift towards enhanced precision and productivity. These advanced machines empower manufacturers to create intricate designs with greater ease, accommodating increasingly complex geometries that demand high attention to detail. As industries seek to optimize their operations, the integration of 4-axis capabilities allows for more versatile applications across various sectors, from aerospace to medical equipment.

Moreover, the 2025 Canton Fair highlights a growing emphasis on automation and smart technology within CNC machining processes. With the rise of IoT connectivity, manufacturers can leverage real-time data analytics to monitor and optimize machining operations. This trend not only improves operational efficiency but also reduces downtime, allowing companies to remain competitive in an ever-evolving market. As a result, the fair acts as a critical hub for industry leaders to explore these emerging trends, fostering collaboration and innovation that will shape the future of CNC machining technologies.

Key Innovations in 4 Axis CNC Machining Centers for 2025

The global CNC machine market is on a robust growth trajectory, anticipated to expand from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, with a CAGR of 9.9%. This growth underscores the increasing demand for advanced machining solutions, particularly innovations in 4 Axis CNC Machining Centers, which are crucial for enhancing precision and efficiency in manufacturing processes. As we approach the 2025 Canton Fair, it becomes essential to delve into cutting-edge technologies that are reshaping this sector.

Key innovations in 4 Axis CNC Machining Centers include enhanced software integration and automation capabilities, enabling manufacturers to achieve higher productivity and reduce operational costs. These advancements not only support Industry 4.0 initiatives but also lay the groundwork for Industry 5.0, where human-centric manufacturing is a focus. As showcased at events like TIMTOS 2025, integration and innovation are driving forces that are pushing the boundaries of what's possible in CNC machining.

Tips: To stay competitive, manufacturers should invest in training their workforce on the latest CNC technologies and software solutions. Leveraging simulation and optimization tools can lead to significant improvements in production efficiency. Additionally, adopting smart manufacturing practices will enable businesses to better respond to market demands and enhance operational flexibility.

Impact of Technology Advancements on Manufacturing Processes

At the forefront of the 2025 Canton Fair, the emphasis on advanced technologies is transforming manufacturing processes significantly. The integration of systems such as industrial robots, control devices, sensors, and machine vision within manufacturing facilities is paving the way for automation and data-driven operations. This technological advancement is not merely about enhancing efficiency but also about enabling factories to evolve toward high-end, intelligent, and environmentally friendly production.

The transition into the era of digital intelligence is crucial as it aligns with China's broader goals for industrial upgrading. By adopting new generation information technologies, companies are accelerating their smart transformation, leveraging artificial intelligence to enhance productivity, and fostering a more resilient industrial ecosystem. The focus on innovative manufacturing models, such as smart manufacturing and service-oriented manufacturing, signifies a commitment to high-quality development amidst the ongoing shifts brought on by the digital economy and technological revolution.

Sustainability and Efficiency in CNC Machining at the Fair

At the 2025 Canton Fair, the spotlight will shine on sustainability and efficiency in CNC machining, particularly through the latest advancements in 4-axis CNC machining centers. These innovations are not only reshaping manufacturing processes but also aligning with the growing demand for eco-friendly solutions. Emphasizing energy-efficient operations, manufacturers are integrating smart technology that reduces waste and optimizes power consumption, thereby minimizing the environmental impact of machining activities.

Moreover, the fair will showcase how these 4-axis CNC machining centers enhance productivity without compromising on sustainability. By utilizing advanced materials and processes, these machines can achieve complex designs with greater precision and fewer resources. On display will be innovative features such as real-time monitoring systems and adaptive machining capabilities, ensuring that manufacturers can maintain high efficiency while adhering to strict environmental standards. The emphasis on both sustainability and efficiency reflects a crucial shift in the industry towards responsible manufacturing practices that cater to the growing eco-conscious market.

Exploring Industry Trends at 2025 Canton Fair with 4 Axis CNC Machining Center Innovations

| Feature |

Description |

Impact on Sustainability |

Efficiency Improvement |

| Energy-efficient Drives |

Advanced motors that reduce power consumption |

Lower carbon footprint during operations |

Increased operational hours with less energy |

| Biodegradable Coolants |

Eco-friendly coolants that decompose easily |

Reduced environmental pollution |

Improved machining efficiency through better cooling |

| AI-based Monitoring Systems |

Real-time data analytics for machine performance |

Optimization of resource usage |

Reduction in downtime through predictive maintenance |

| Modular Machine Design |

Configurability for diverse machining tasks |

Lower material waste through efficient setups |

Faster changeovers between tasks |

Market Opportunities and Challenges for CNC Innovations in 2025

The CNC machining industry is poised for substantial growth, with the global CNC machine market projected to expand from $101.22 billion in 2025 to $195.59 billion by 2032. This remarkable growth represents a compound annual growth rate (CAGR) of 9.9%, underscoring the increasing demand for precision manufacturing across various sectors. As the 2025 Canton Fair highlights innovative 4 Axis CNC machining centers, businesses are presented with unique market opportunities to adopt these advanced technologies, which enhance operational efficiency and precision.

However, this growth also brings challenges. Companies must navigate issues such as supply chain disruptions and a skilled labor shortage, which could hinder their ability to fully capitalize on technological advancements. Additionally, the rapid pace of innovation in CNC machinery necessitates continuous investment in training and development to keep the workforce adept and competitive. Stakeholders in the CNC market must strategically address these challenges while leveraging emerging technologies to secure a robust foothold in an evolving landscape, positioning themselves for success in the market of the future. The upcoming Annecy Festival provides an exceptional networking platform to explore collaborations that can harness these advancements, particularly for businesses seeking to produce high-quality outputs.